Safe Landing

Foamax, a leader in the Polish fire safety equipment market, has developed the Safe Landing system. The development of the firefighting system was preceded by the execution of airport projects and the securing of a helipad on one of the buildings in Warsaw. The system incorporates proven fire safety solutions from well-known manufacturers, including TYCO, ANSUL, SKUM, ZETTLER, and GRINELL.

This system has been designed for clients the user all types of landing facilities. It consists of devices that hold the required certifications and standards, taking into account local conditions and capabilities, as well as the type and quantity of potential flying objects using the helipad. FOAMAX's solution ensures comprehensive fire protection for the landing facility/helipad to the user or owner.

APPLICATION

SAFE LANDING is a firefighting system that allows for the rapid coverage of the entire helipad surface with specially selected firefighting foam using firefighting monitors. This foam is flame-resistant, capable of withstanding the high temperatures generated during the combustion of aviation fuels, and resilient to the corrosive effects of helicopter operational fluids.

OPERATING PRINCIPLE

The system operates automatically, initiated by a single button press, by anyone who finds themselves in the immediate vicinity of a hazardous situation. Specialized training or skills are not required, which can be lacking in stressful situations.

The primary component of SAFE LANDING is the firefighting monitors. They offer the advantage of being able to extinguish with a concentrated or dispersed stream. However, the primary operating mode is automatic oscillation, ensuring comprehensive coverage of the designated area with an effective layer of specialized firefighting foam. Upon the client's request, the activation of the firefighting system can also send a fire alarm to the airport dispatcher, fire department, or other dedicated response service

SYSTEM COMPONENTS

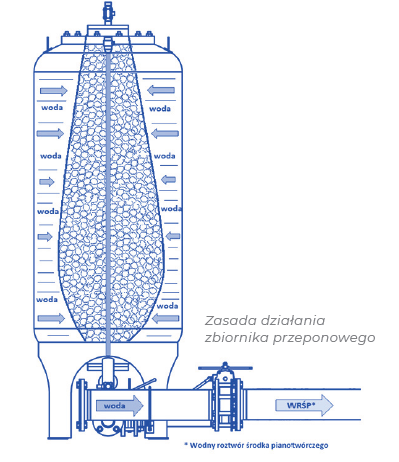

The Bladder Tank - It is one of the key components of a balanced foam concentrate dispensing system. The bladder tank is constructed from steel and contains a rubber bladder (membrane) filled with a supply of foam concentrate. The bladder tank is used for storing and dosing foam concentrate for water-foam firefighting systems with variable flow rates and/or pressures. Its operation does not require external power other than the pressurized water system. All that is needed is a hydrant network or a small water pump station, along with a water storage tank for fire-fighting purposes.

Horizontal Bladder Tank

Schematic of the SAFE LANDING system using the BLADDER TANK device in the vertical version

The TPW series proportioner precisely dosing the foam concentrate across a wide range of flow rates and varying pressure values. It is made of brass, easy to install, and suitable for use in all types of foam systems. The TPW proportioner is used in conjunction with the bladder tank. This combination of dosing and storing foam concentrate ensures excellent foam production parameters. Accurate foam concentrate metering, regardless of flow and pressure, is crucial for the proper operation of the system and its firefighting effectiveness.

The TPW series proportioner precisely dosing the foam concentrate across a wide range of flow rates and varying pressure values. It is made of brass, easy to install, and suitable for use in all types of foam systems. The TPW proportioner is used in conjunction with the bladder tank. This combination of dosing and storing foam concentrate ensures excellent foam production parameters. Accurate foam concentrate metering, regardless of flow and pressure, is crucial for the proper operation of the system and its firefighting effectiveness.

The test conducted in accordance with the PN-EN 13565-1 standard for the dosing accuracy at a concentration of 3% for the TPW 150 series dispenser showed a value of 3.08%

The recommended foam concentrate is SKUM AFFF 3% EG

It can be used with tap water, seawater, and contaminated water. It creates a water film on the fuel's surface. Its composition combines fluoro and hydrocarbon surfactant technologies, highly effective for extinguishing hydrocarbons. It is used at a 3% concentration with water. The product's action aims to quickly extinguish the fire by utilizing extinguishing mechanisms:

- Dense and sticky foam blocks the supply of oxygen necessary for the combustion process.

- The water film formed on the liquid's surface (fuel) blocks the release of fuel vapors, thus sealing the burning hydrocarbon's surface.

The product complies with the EN 1568:2008 1.3 standard and ICAO level B requirements for firefighting agents used in aviation.

FJM Water-Foam Monitors 80 WTO

Monitors are the most essential component of the system. They allow for the delivery of a water stream or firefighting foam over significant distances with a wide flow range:

FJM 80 - capacity from 500 to 3700 lpm, throwing range approximately 70 meters.

The monitors has also been additionally tested in an accredited laboratory for the following operating parameters:

- flow 400 lpm at @ 5 bar, throwing range approximately 30 meters

- flow 400 lpm at @ 7 bar, throwing range approximately 31 meters

- flow 500 lpm at @ 5 bar, throwing range approximately 31 meters

- flow 500 lpm at @ 7 bar, throwing range approximately 34 meters

The WTO series is additionally equipped with a water-powered turbine that enables automatic oscillation. The special design and carefully chosen materials make the monitors durable, resistant to corrosion, and high temperatures, which significantly impacts the effectiveness of firefighting operations in the event of direct exposure to surface fires (fuel spills). This solution works excellently for helipad protection. The pipeline system, valves, automatic activation system are always configured to meet the specific location's needs. This required infrastructure is fine-tuned during the design phase.

SYSTEM

The SAFE LANDING system offers undeniable advantages, including the ability for remote activation without exposing the system operator (as is the case with direct use of handheld firefighting equipment) and the capability to extinguish flames and high temperatures in close proximity.

- The system is complete, designed "turnkey" for a specific location.

- The system is built based on effective, certified solutions.

- The system is remotely activated, ensuring operator safety.

- Operating the system does not require specialized firefighting skills.

- The system is intuitive, ideal for stressful situations, and operates automatically.

- When used correctly, after checking and replenishing foam agents, the system is ready for reactivation.

- The system is ready for use in all weather conditions, 24/7.

In the process of designing, there is the possibility of configuring individual elements, such as increasing the number of firefighting monitors or the number and type of bladder tanks (e.g., V-type vertical or H-type horizontal). The system can also be expanded to include a Fire Alarm System (FAS) with Audible Warning Devices (AWD) or additional components (e.g., an addressable signal to the nearest fire department unit, etc.).

The FJM WTO Water-Foam Monitor on an Elevated Helipad

Destiny

This solution is dedicated to heliports and helipads. It is ideally suited for securing landing sites at hospitals, private landing pads, and anywhere where the arrival of rescue services is challenging (difficult terrain, remote locations, private properties). The system is applicable to heliports, ground-based helipads, and there are no restrictions on installing it at height, such as on building rooftops, ship helidecks, and anywhere safety measures are required for helicopter crews.